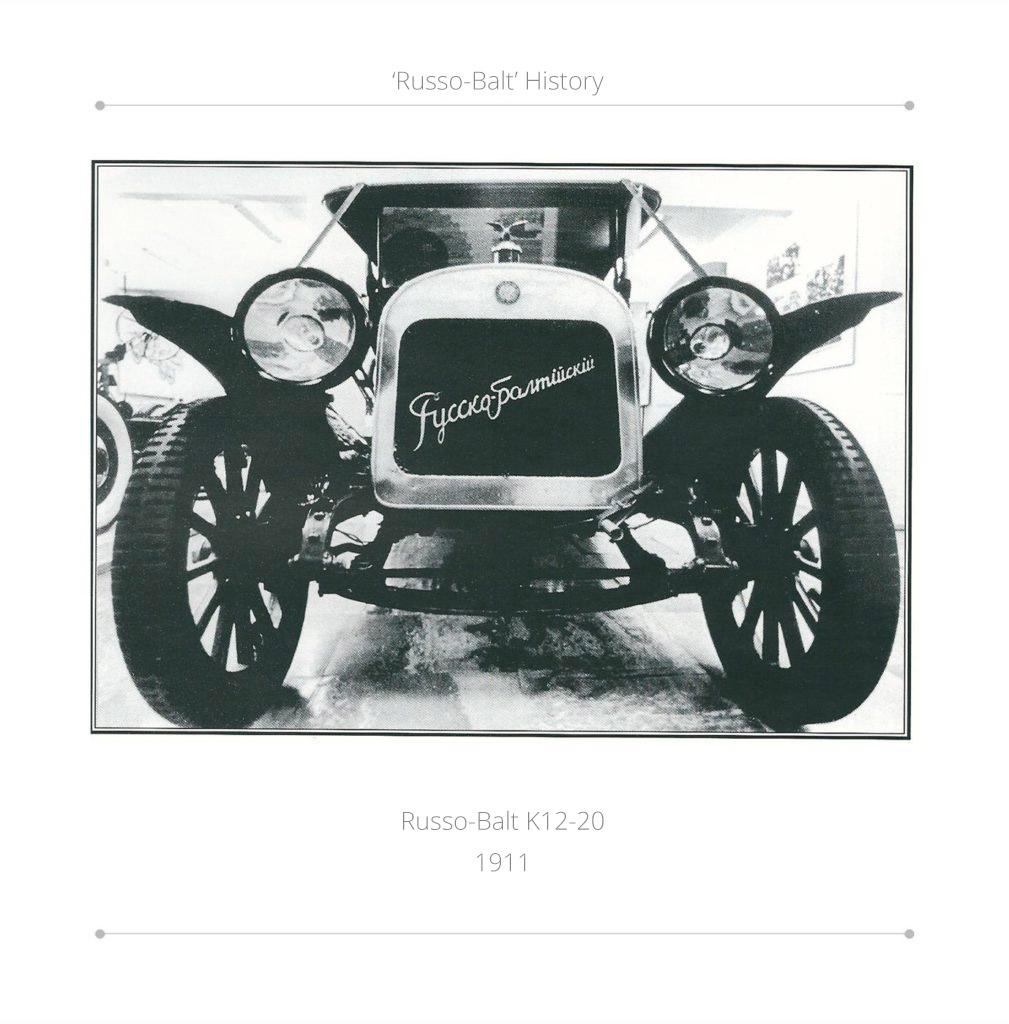

On 19 July 1910 the Board of the Russian-Baltic Railroad Car Factory in Riga informed the state engineering department that it starts an airborne vehicle department. In 1911 the airplane factory was established in Riga. It started the production of French ‘Sommer’ airplanes. In the January of 1911 transport engineer A. S. Kudashev was invited to a company. He was famous for building an airplane of his own design. Two more talanted engineers joined the company later: I. I. Volkovsky and J. M. Gakkel. After the test pilot V. F. Smith crashed during a demo flight the ‘Sommer’ airraft production was cancelled. Moving the aircraft factory to St. Petersburg would be profitable for a company so they closed this branch on 27 May 1911.

So in 1912 after the chairman of the ‘RBVZ’ board Mikhail Shidlovsky a new airborne vehicle department opened next to the automotive department on the Stroganovskaya embankment. It already had orders as in autumn of 1911 we got an order for licensed production of ‘Farman’, ‘Blerio’ and ‘Newpor’ aircrafts.

M. Shidlovsky was looking for a great professional capable of leading the company engineers. As a result he found a student of Kyiv Politechnical University Igor Sikorsky. In march 1912 RBVZ signed a contract with Sikorsky to build airplanes of his design. Sikorsky as a head aircraft engineer and designer managed to transform a small aircraft department to a large factory later called ‘AviaBalt’.

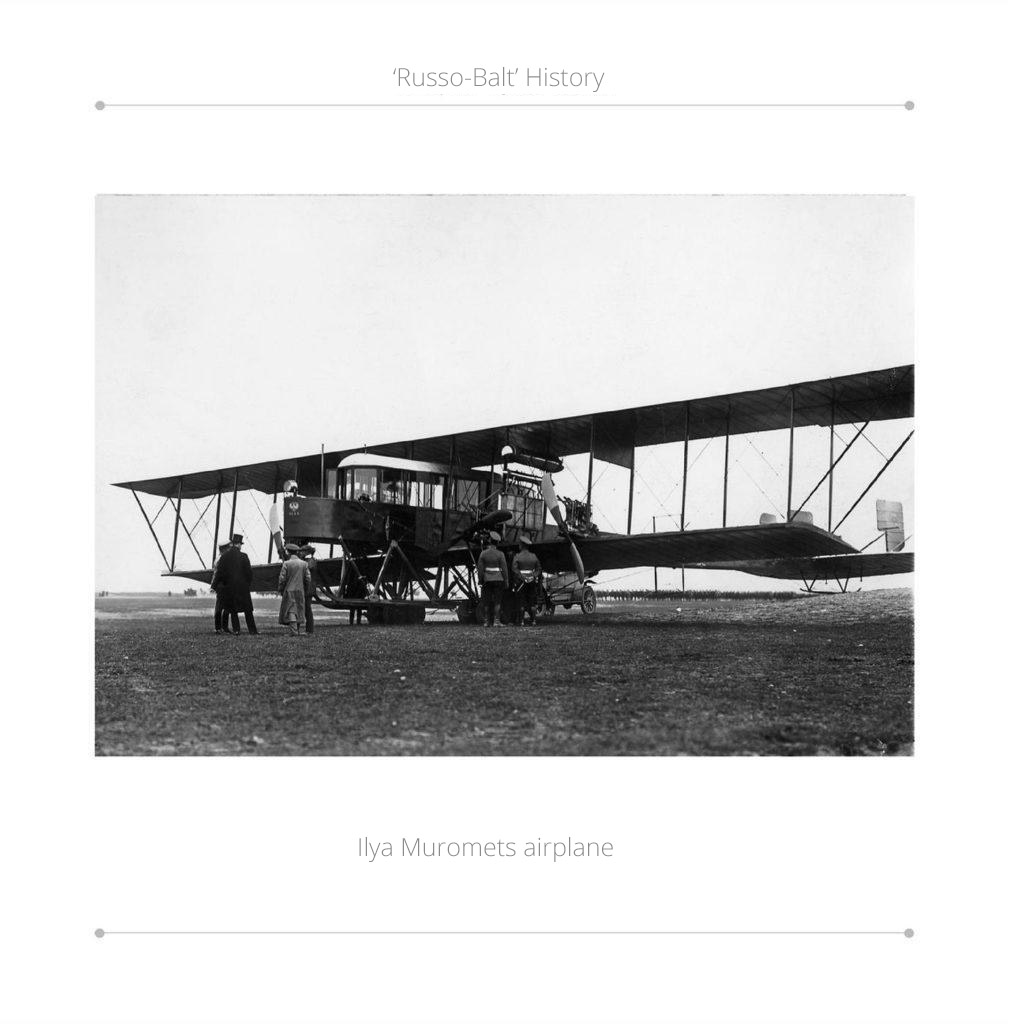

AviaBalt designed and built first Russian fighters and atack aircrafts. But it’s most famous creation is a 4-engine long-range bomber ‘Russky Vityaz’ (Russian knight). Later it was called ‘Ilya Muromets’. It took a first flight on 23 December 1913. A year later, on 23 December 1913 the army issued an order to form a first bombing squad consisting of ‘Ilya Muromets’. This day is known as a day of the Russian long-range airforce establishment. During the World War I Mikhail Shidlovsky took a personal command of ‘Ilya Muromets’ squadron and lost only 1 aircraft during the conflict. But at that time this aircraft was better known for a non-stop flight form St. Petersburg to Kyiv in 1914, a hometown of I. I. Sikorsky and V. I. Kislichenko. AviaBalt produced a total of 240 different aircrafts during a period from 1912 to 1917.

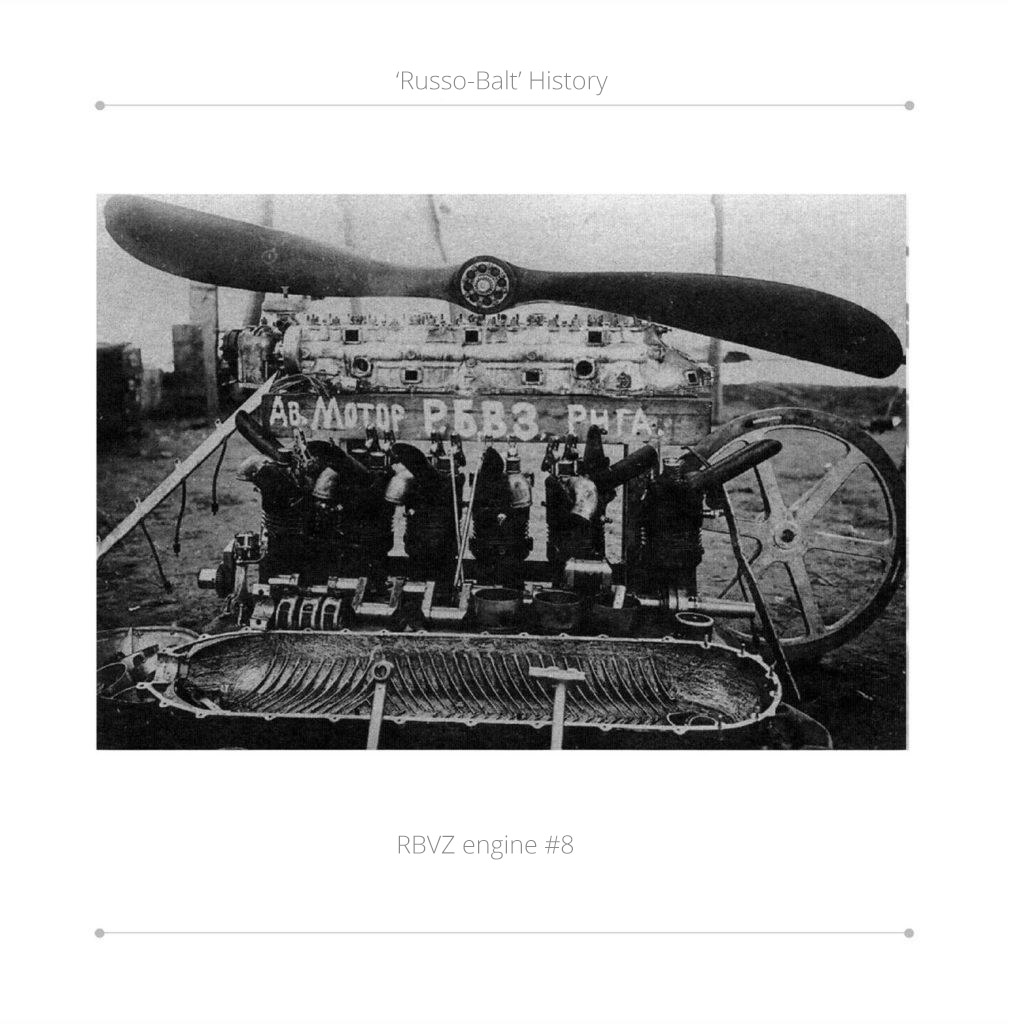

After the World War I the chairman of the board of the Russo-Balt company started a competition to design an airplane motor, a substitution for a German ‘Argus’ motor used on ‘Ilya Muromets’. This engine was no longer available due to a war. Two groups of engineers joined the competition. First group was lead by V. V. Kireev, an engineer of Russo-Balt factory in Riga. I. I. Sikorsky lead the second group located at the RBVZ factory in St. Petersburg.

Sikorsky’s engine was a 140 h.p. copy of ‘Argus’. Kireev’s engine was based on a ‘Benz’ aircraft engine and it had 150 h.p. So Kireev’s engine was a winner and our company started preparing it for a mass production in Riga. It was a 2-stroke inline 6-cylinder water-cooled engine. It had a car-type radiators on both sides. The propeller was mounted on it’s crankshaft without a gearbox. After Riga department was evacuated to Petrograd (that was the name of St. Petersburg between World War I and the Revolution) the first batch of 5 engines was made. The following engines were marked as ‘RBVZ-6′ and there was a total of 45 engines. They were mounted on “Ilya Muromets’ aircrafts of V and G series.

In the summer of 1915 due to German incursion to Latvia and a danger of losing the city of Riga the rest of our factory was completely evacuated to Moscow, Tver, Taganrog. Automotive division moved to Moscow, railroad car division moved to Tver and the agricultural machinery division moved to Taganrog.